The RH High Pressure Suction System is designed for localized treatments on paper. The vacuum is controlled from the stainless steel control panel and is displayed in hectopascal on an LED digital display together with the % of vacuum being used. The exhaust air is discharged through a 3 m long, 100 mm diameter flexible duct and when not in use the duct retracts into the side of the pump. A 16 mm diameter flexible hose connects the RH High Pressure Suction System surface to the pump just beside the exhaust duct.

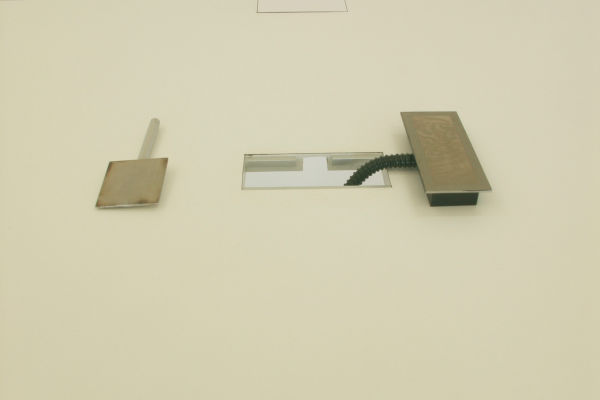

The suction surface is very fine sintered copper/nickel alloy that in appearance resembles a piece of matt stainless steel and, when fitted, is flush with the top surface of the platen or table top. The effective area of suction on the suction surface is 50 mm x 150 mm, although the surface extends 10 mm beyond this on all edges. The RH High Pressure Suction System can be supplied with an anodised aluminum platen with holes in 2 positions to fit the suction surface or with a table top with 4 suction surface positions that fits onto a standard RH Table Frame 1600 mm x 1200 mm.

Alternatively, a scale drawing of the hole required to fit the suction surface into an existing table top can be supplied. The RH High Pressure Suction System is quiet, producing 62dBA at 1 metre during operation, and is powered by an industrial single phase electric motor for continuous operation from a standard earthed power outlet of 220-240 V, 10 A, 50/60 Hz.

Specifications subject to change without notice.